The Power of Heat

K Thermo is part of ALC , the cutting-edge Italian Adhesive Leading Company with 100 years of extensive experience in the adhesive industry.

-

The power of bonding to every need.

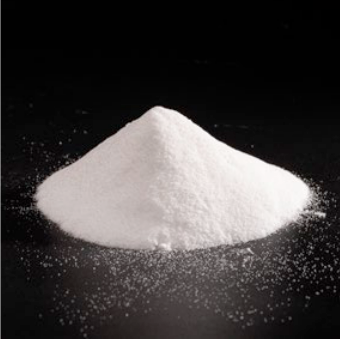

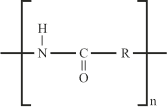

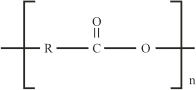

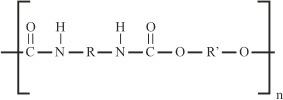

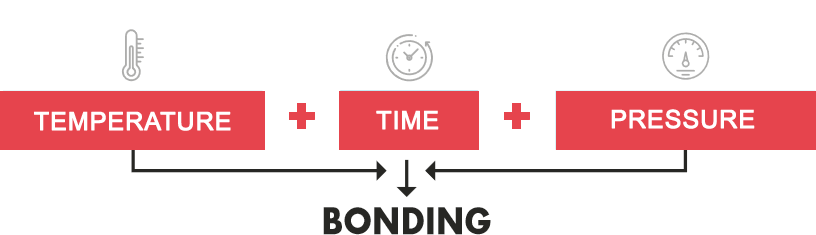

Our technologically advanced and environmentally friendly adhesive solutions are designed to satisfy any request. Available in granules, powder, film, web, and net forms, each of our thermoadhesive products bonds surfaces seamlessly when subjected to specific heat and pressure.

-

The power of an eco-friendly journey.

We deliver products that are not only highly effective but also eco-conscious. Being aware of the importance of sustainability, we are committed to minimizing our environmental footprint.

-

The power of excellence and innovation.

Count on our team of experts to assist you in selecting the perfect adhesive for your needs. Expect nothing but top-notch quality, reliability, and sustainability. We’re excited to embark on this journey with you and provide the best adhesive solutions available